25mm.

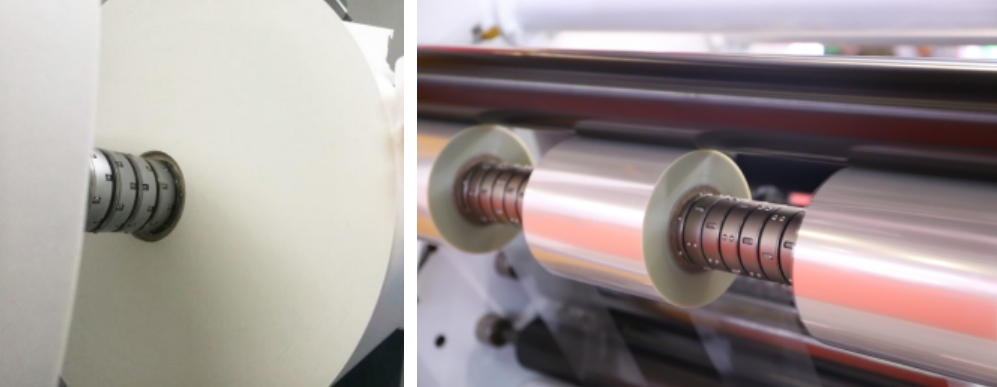

The Top A series machine is our hot seling model, also the most cost-efficient type for electronic protective film, optical film, PI film,PET/BOpp flexible film, etc. slitting and rewinding.

TOP A SERIES High Speed Slitting Machine pressure sensitive adhesive slitting machine is our most popular machine, which can both used for label paper such as Silicon Coated Paper, Metalized Paper, Self-adhesive Paper and flexible, such as PET/BOPP/PE etc protector film ,optical film, release film, laminated film, bond paper, matte couche, paper semi-gloss paper, thermal transfer paper, direct thermal paper, metallized paper, cardboard paper, thermal cardboard etc slitting and rewinding.

This machine owns the following advantages:

Shaftless loading for jumbo roll, 1 worker can loading jumbo roll.

Friction shaft rewinding, perfect slitting effect in high speed, 400m/min

3 sets servo motor control, 1 set 5.5kw for traction, 2 sets 7.5kw for 2 rewinding section.

Technical parameter | ||

Machine model | HCH3-1300A | HCH3-1600A |

Max slitting speed | 400m/min (depend on material) | 400m/min (depend on material) |

Unwinding width | 1300mm | 1600mm |

Unwinding diameter | Φ1200mm | Φ1200mm |

Rewinding diameter | 2*φ600mm | 2*φ600mm |

25mm.

Yes, ok. Shaftless chuck support both 3 inch and 6 inch.

Yes ,can equip 6inch friction ring to support.

Machine as usual is integrated and we do not dismantle before delivery.

So just connect the power cable and air pipe is ok.

For the operation, we take instruction video for all customers before delivery to guide you how to operate, and provide the instruction file.

Also we provide service: our engineer and technician open live training until you learned it and run it well.

12 months guarantee, life-long time technic maintenance and support. 24 hours feedback when receive the client writing maintenance proposal.

Any part damage caused by non-human factors within the warranty period can be replaced for free, excluding machine consumable parts. Maintenance of part damage caused by violation operation or mis-operation of operators will be charged with costs of parts.

The price of spare parts exceeding the warranty period shall be the lowest ex-factory price of the seller.

For extra accessories beyond the standard configuration of contractual machine, the price shall be the lowest ex-factory price of the seller.

Any time you have question about slitter, we are always here to provide service.

In the year of 2024 ,a customer named “Termirollos “ from Mexico ,they wanted to slit label stock and tend to find a supplier of the labelstock slitter from China, They have found several slitting machine manufacturers in China but are confused about which one to select, since the technical data appears quite similar. Among these manufacturers, there is one whose price seems much lower if they don’t conduct an on-site inspection of the factory—and this is really a challenge for them.

We have a customer from Venezuela named Cesar ,which knew our machine very well as they have had customer used our slitter and ran very well .

The lucky thing is the customer “Termirollos “ boss Luis ,he knew cesar and believe him .

So Luis listented to cesar’s advice ,and he also made much study on our slitter , from youtube ,website ...

He found that Raloyal slitter have many advantages: for the tension control /the knife clean/the operator convenience care,etc .

Thus Luis choosed us as their label stock slitting machine supplier ,and the result is : They are happy .

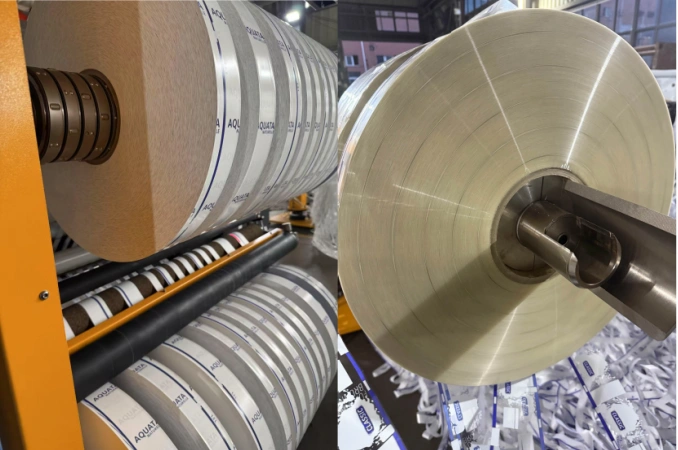

The slitting effect and run video in their plant below .

In the film industry:

As expressed earlier ,the TOP A slitter can slit not only label stock ,but also flexible film and foil .

Embe as the biggest printing (owns 7 print houses ) manufacturer in Poland , the major supplier of Coca Cola ,they have strict demand for the bopp film slitting and rerwinding .

In April of 2025 ,the plant general manager Andrzej , came to Raloyal plant for the first time contact and factory inspection

The machine details and the plant 5S site management which impressed him much.

After the continuous of the machine details and technic discussion , Embe and Raloyal concluded the slitting machine smoothly ,now the machine have finished and have approved the FAT by EMBE .

The machine FAT photos and video are below .

In November this year, we will dispatch a service technician to Embe, and we believe it will be a nice journey for Raloyal. Meanwhile, we will learn how our customers work and what they care about most in the slitting process—their needs are our actual focus.